ON HAND KEY PROJECTS WITH LOCAL TECH SUPPORT FOR BORDER INDUSTRIAL COMMUNITY

Some of our Training Courses

Injection Molding Training

This course help to standardize the basics for all molding area involved people.Operators, Technicians, Quality Auditors, and Tool Room personnel are welcome to take this training.

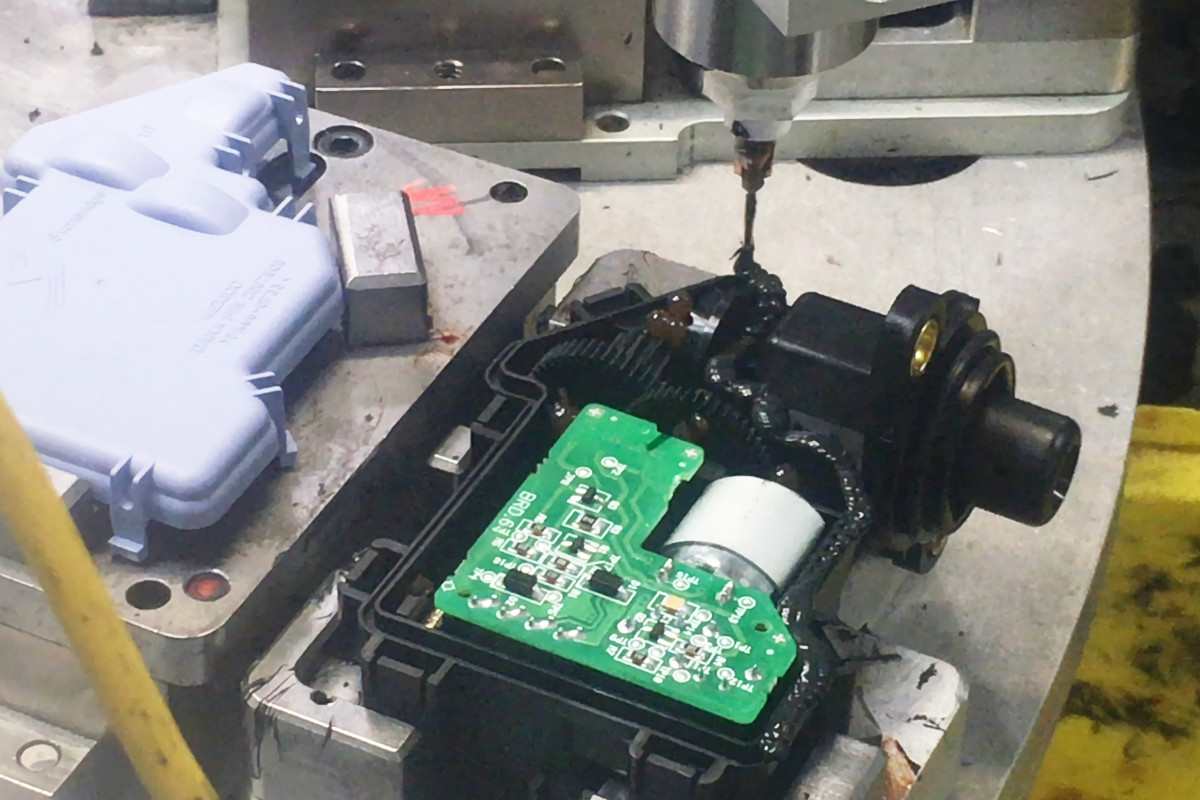

Mold and Machine Setup Training

This is a HANDS ON training focused to directly involved personnel with the machine controls. Process Technicians and Engineers must take this training to standardize the machine setting procedures and to make sure all molds are being running correctly.

Molding Process Troubleshooting

The participants will be trained to use Engineering Tools

Mold Validation Training

The participants will be trained to generate documentation that meets standards of Manufacturing in Injection Molding, as well as its use to support the release of a Robust process and capable of production.

Mold Maintenance

In this course, the participants will be trained to Mold Maintenance and repair the mold

Mold Setup

Participants will be trained to configure:

1 KISS Axiom for Plastics Designs

- Cycle time Calculations

- REF, KPC and QCI Identification

- Projected Area calculations

- Tonnage Requirement Calculation

- Clamp and Injection Machine Controls

- Molding Cycle Analysis

- Clamp Set Up and Mold Protection Settings

- Injection Set Up

- Sampling Procedure

- Start up and Shutting Down Procedure